Where is the Salmonella hiding?

It all starts at a trade show. That’s where we meet an extraordinary microbiologist: Philippe Armaing.

Philippe is a hunter. Not of big game, no. What he hunts are bacteria, specifically Listeria and Salmonella.

His job? Tracking down stubborn contaminations for Mérieux NutriSciences.

When a food production plant can’t get rid of a contamination, it’s Philippe they call.

Like a microbiological Dr. House, Philippe has spent the past 20 years going from one production site to another to solve complex mysteries.

Safe to say he’s seen his fair share of contaminations. And stories? He’s got plenty.

And lucky us, he agreed to share one of them, just for us.

A story that’s we could have called: “The contamination is never where you think it is”.

Best QC strains

Food & Water : The best QC Strain suppliers

We polled the SuperMicrobiologists.

Here are their favorite QC Strains

Crisis Situation: Salmonella Contamination

This case takes place in a frozen vegetable factory.

For the past 6 months, they’ve been struggling with a Salmonella contamination, without understanding where it’s coming from.

Even worse: customer complaints are pouring in, and some are refusing entire batches.

After six months of internal investigations, the food company finally calls in an expert: Philippe.

The Situation

When Philippe arrives, here’s the picture:

Six months ago, a customer reported finding Salmonella in a product.

The factory ran tests on both the environment and the products. Nothing showed up.

But complaints kept coming. Customers regularly found Salmonella in the frozen vegetables.

So the factory ramped up the sampling.

This time, a few samples came back positive, but without any clear pattern.

Environmental samples? All negative. The mystery deepens.

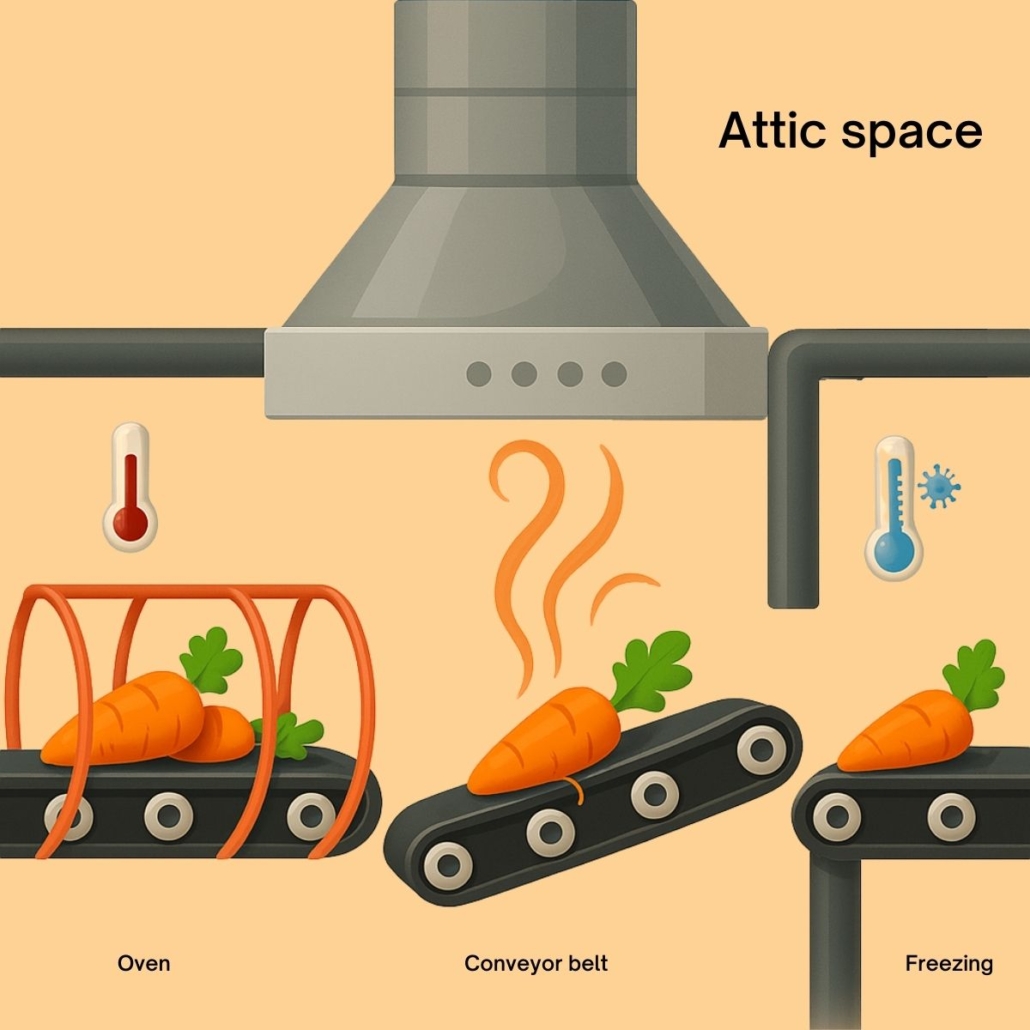

The Production Area

This factory produces frozen vegetables packed in 5 kg bags.

The vegetables are peeled, cut, washed, cooked, frozen, then packaged.

Here’s what the “problem area” looks like:

The critical part of the process is between the end of cooking (where no Salmonella should survive) and packaging.

Chances are, the contamination is happening in one of these steps:

- Cooling

- Freezing

- Packaging

Philippe is there… watching. He observes the cleaning routines, the zoning.

Then he samples: before cleaning, after cleaning, and after restarting the machines (to check for the infamous “release effect”).

The result? Nothing. Zero Salmonella.

But Philippe doesn’t stop there.

Something Feels Off

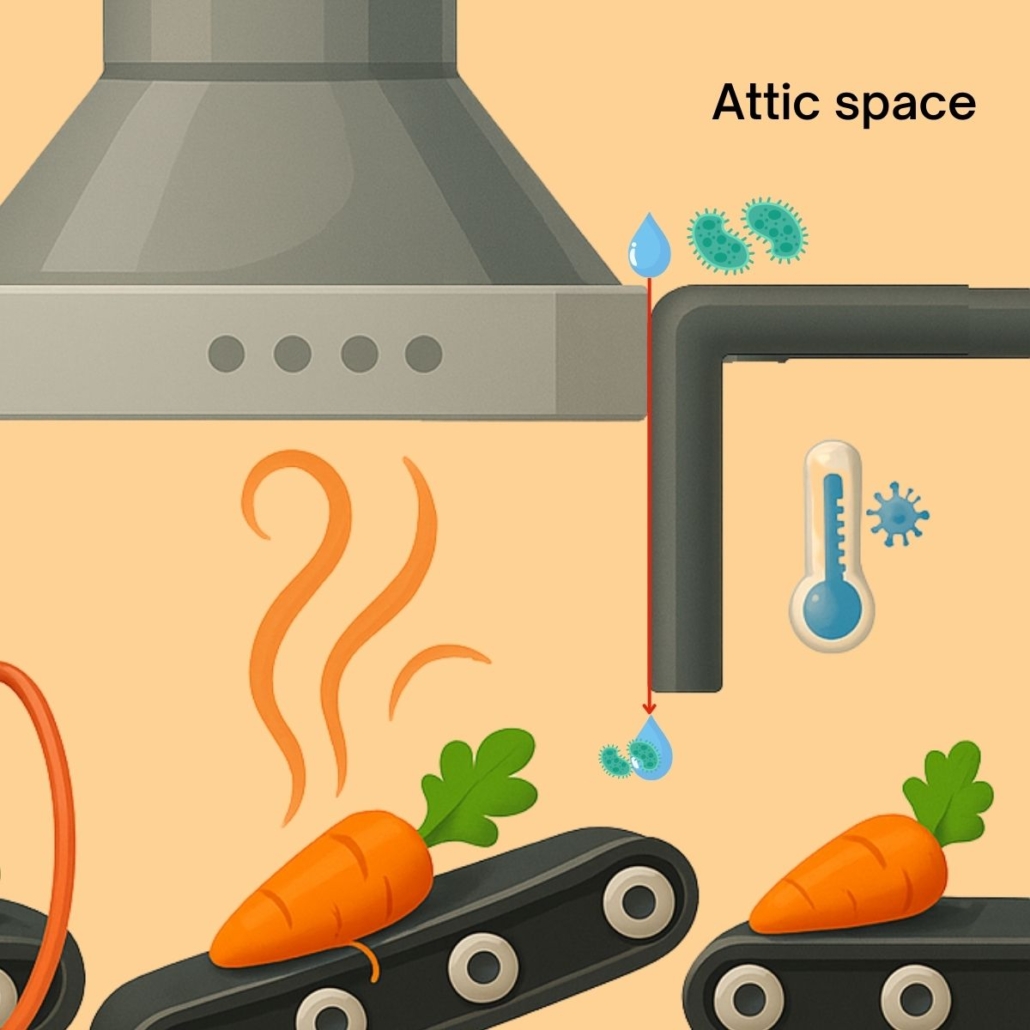

During production, he looks up. In the cooking room, despite the big exhaust hood, there’s condensation on the walls, right at the entrance to the freezing tunnel.

Where the conveyor belt passes through the wall, Philippe notices something strange.

Condensation is building up on a metal trim jointed directly above the conveyor!

Looking closer, he sees that every 45 seconds, a drop of water forms at the joint… and guess where it lands?

Bingo: on the vegetables.

Philippe’s got a lead.

Next Stop: The Attic

Dr. House-style, Philippe asks to go above the production zone, into the attic.

And there… surprise (or not): total chaos.

“Very few quality managers go up into the attic, and yet it’s often the most revealing place.”

Philippe “House“

There’s moisture everywhere.

The heat from the cooked vegetables meets the cold of a poorly insulated attic.

The result? Condensation.

But that’s not all.

On the floor, Philippe sees something that doesn’t belong… a feather.

Where there’s a feather, there are… birds.

No time to lose, he asks for a tall ladder. Time to check the roof.

On the Roof

Up there, it’s even worse.

Seagulls are nesting next to the vapor exhausts (and who can blame them, it’s warm).

The roof is covered in 4 to 6 centimeters of… guano.

Yes, you’re visualizing that right.

The Source of the Contamination

Philippe goes back down and starts a new round of sampling: around the attic exhaust area and on the metal trim joint.

The result is crystal clear: Salmonella everywhere.

The investigation is almost over. The root cause is obvious:

- Seagulls have colonized the roof.

- The non-watertight roof lets guano, loaded with Salmonella, into the attic.

- The exhaust hood isn’t sealed, so steam makes its way into the attic.

- In the attic, the steam condenses into tiny droplets, now carrying Salmonella.

- These droplets slide down the faulty hood joint, travel down the wall, and form a droplet right above the vegetables.

One contaminated drop every 45 seconds. That’s one “hit” every 10 five-kilo bags.

With 25 g sampled per bag, the odds of detection were about 1 in 2,000.

Now we understand why the detection seemed so “random”!

Corrective Actions

After Philippe’s intervention, the company took the following steps:

- Fully sealed the roof

- Completely cleaned the attic

- Properly sealed the exhaust hood

- Reassembled the metal trim correctly

And guess what?

No more Salmonella contamination … at least caused by the guano!

Conclusion

A Salmonella contamination in vegetables… after cooking? That’s unusual, and hard to detect in the final product.

But as often happens, the root of the problem lay in the very design of the site.

Philippe needed just two days on-site to solve what had dragged on for six months.

His advice?

Always check what’s going on above the production zone — in the attic.

That’s where the real surprises hide.

If you too have stories of contamination to share with us, contact us – we love it!

Leave a Reply

Want to join the discussion?Feel free to contribute!