Pharma Microbiology: How to crush tablets?

“Super Transparent” Article

Interscience asked us to write an article on this particular subject. They gave us complete freedom in writing it (and that’s really cool).

In the non-sterile pharmaceutical industry, to start the microbiological analysis of a drug tablet, it first needs to be dissolved… And that can be a real hassle.

To facilitate this step, several pharmaceutical labs have adopted a technology that comes directly from food microbiology (for once it’s the other way around!). This technology is; The laboratory blender.

However, be warned, even though using a lab blender greatly helps microbiologists, this step is not without… risk.

We interviewed several QC (Quality Control) microbiologists to understand how they optimized their lab blender use.

In microbiology there is always a risk to… have a “crush” !

Contents:

- Why is it necessary to crush tablets?

- Methods for crushing tablets

- The use of a lab blender

- How to prevent leaks from blender bags?

Why is it necessary to crush tablets?

In the non-sterile pharmaceutical industry, tablets (pills or syrups) are analyzed according to chapter 2.6.12 of the European Pharmacopoeia.

The analysis steps are as follows:

- 10g of tablets are diluted in 90 ml of broth with or without neutralizers.

- The mixture is homogenized (this is the crushing step).

- 1 ml is placed on TSA plates for bacterial counting.

- 1 ml is placed on SDA plates for counting yeasts and molds.

- 10 ml are incubated in enrichment broth to verify the absence of specified microorganisms.

- In some cases, a test to verify the absence of salmonella in 10g of tablets may also be conducted.

Homogenization is, therefore, a crucial step for the rest of the analysis.

The tablets must be completely pulverized to guarantee total extraction of microorganisms from the matrix.

But crushing a tablet (which is often very hard) in a sterile manner is a real challenge.

Methods for grinding pharmaceutical tablets

We asked on LinkedIn what methods SuperMicrobiologists use to grind their tablets and capsules. Here are the results of the survey:

We were surprised by the proportion of microbiologists who still use the mortar and pestle technique.

Before discussing lab blender, here are other techniques used to grind tablets.

The Mortar and Pestle

Very handy for preparing the mint in our virgin mojitos, the mortar and pestle are also used in microbiology labs to crush tablets. The technique is simple: place the tablets at the bottom of the mortar and crush them with the pestle.

Advantage:

- It’s cheap and… it doesn’t break down.

Disadvantages:

- It can be painful for the microbiologist’s joints.

- Not reproducible: Grinding is difficult to standardize.

- It’s an “open” system, so the risk of contamination is significant.

- Instruments must be cleaned and sterilized between each sample.

The Blender

Yet another device for making cocktails… it seems microbiologists only think about that!

In some microbiology labs, this type of blender is used to grind tablets.We put in it 10g of tablets and 90 ml of diluent (TSB or pharmacopeia base).

Advantages:

- The grinding is efficient and quick.

- Reproducible method: Homogenization time can be standardized.

Disadvantages:

- The bowl must be cleaned and sterilized between each sample (if there are several per day, multiple blenders are required).

- They are made of glass, so fragile… This can quickly become expensive if you’re clumsy.

- Several labs reported leaks and also that the blade may break.

- If the lab uses a diluent with neutralizers, it will foam, thus creating an analytical bias (or one must wait for the foam to settle).

- The impact of the blade on the viability of microorganisms raises questions.

The Stirrer with Magnetic Bar

When the composition of the tablets allows it (easily soluble in water), tablets and diluent can be placed in a sterile container, with a magnetic bar on a magnetic stirrer.

The rotation of the bar helps dissolve the tablets. To improve dissolution, it can even be heated… a little. The goal is not to kill the microorganisms either!

Advantages:

- Works very well for pasty forms.

- Does not make noise.

- Reproducible method: Homogenization time can be standardized.

Disadvantages:

- The magnetic stirring bar must be sterilized between each use (and kept sterile).

- Dissolution must occur quickly (10-15 minutes max) to prevent the multiplication of microorganisms.

- A sterile, single-use container must be used.

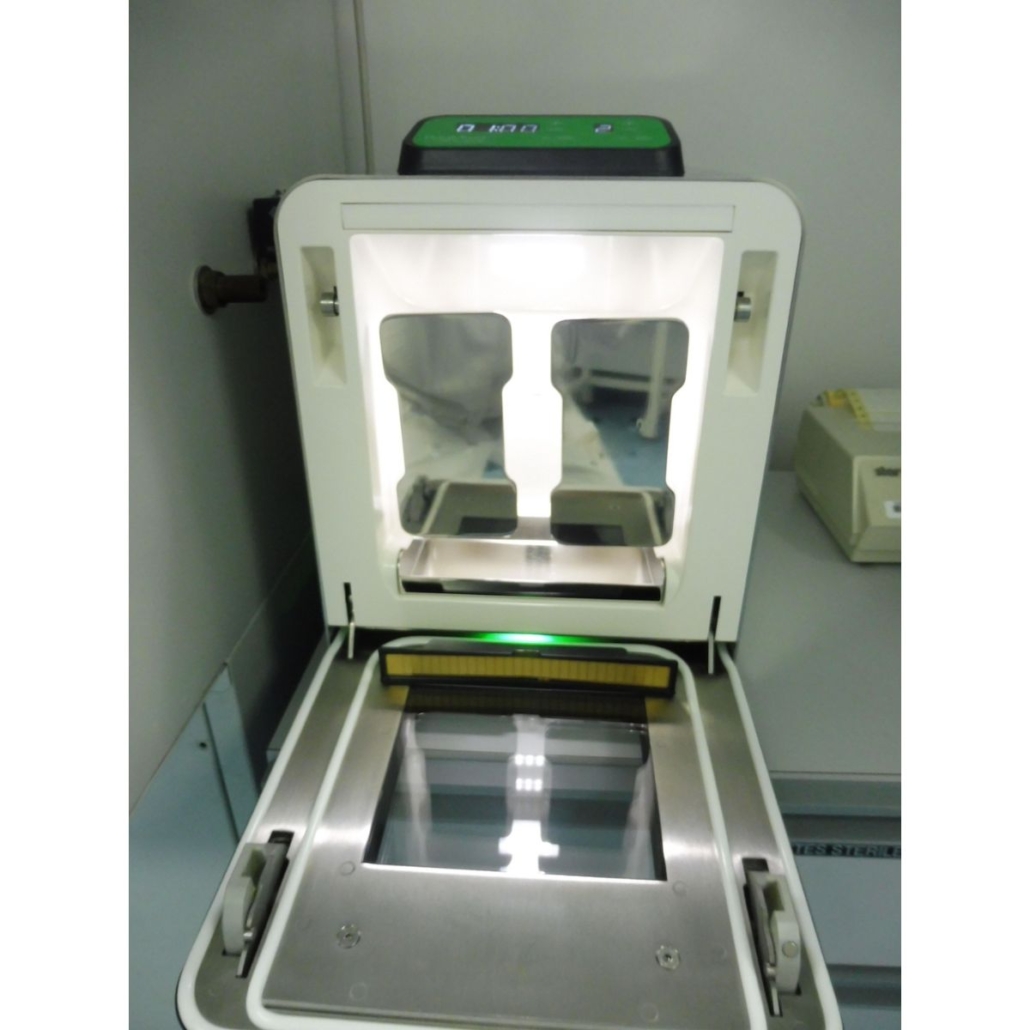

The Use of a Paddle blender

Lab blender used in a pharma lab to crush tablets and pills

Laboratory blenders (or peristaltic blender or Stomacher®… but beware, that’s a brand name) have been used for decades in food microbiology laboratories.

The main advantage of this device is the ability to crush and homogenize a matrix in a diluent without the risk of external contamination.

Tablets and diluent (such as TSB) are added to a sterile bag, protecting the sample. The lab blender’s paddles then crush the tablets.

Advantages:

- Samples are crushed effortlessly in a sterile container (the bag) that is inexpensive.

- Using a bag with a filter prevents pipetting particles that could interfere with reading (particles may look like colonies).

- Eliminates cleaning steps between samples, saving time and also eliminating the risks of cross-contamination.

- Reproducible method: Homogenization time and strength can be standardized.

Disadvantages:

- A peristaltic blender must be purchased.

- The paddle blenders can be noisy… depending on the model, so it’s important to choose wisely!

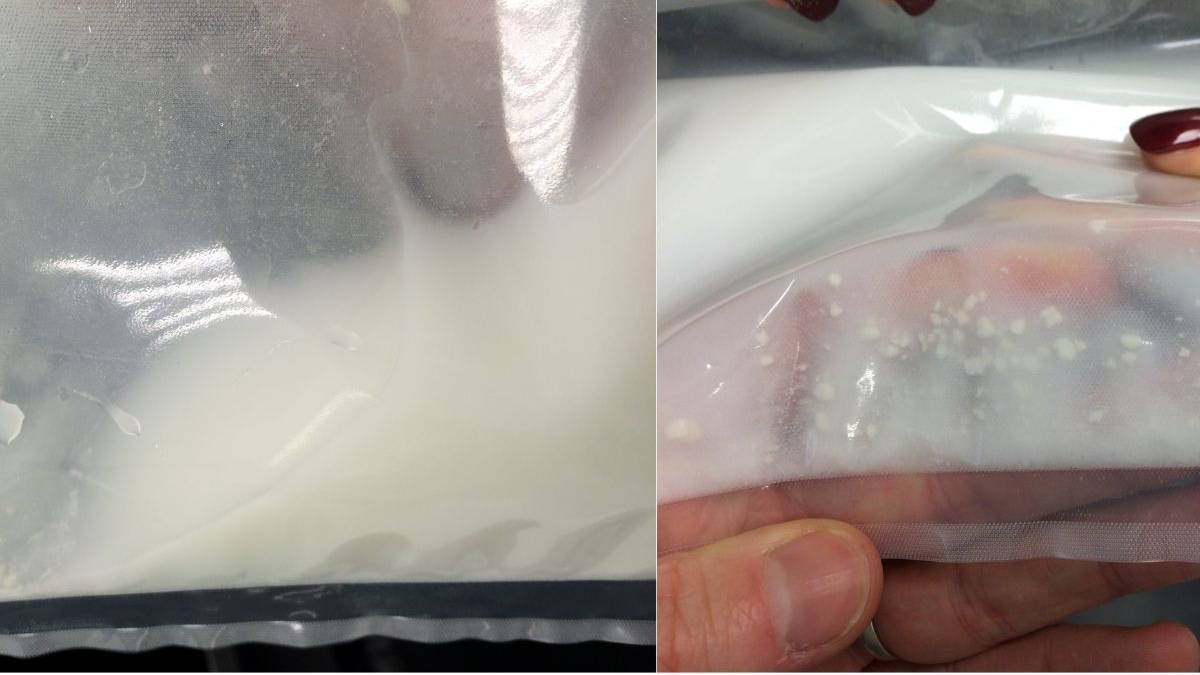

- The bag can burst… and that’s really a hassle!

How to Prevent Leaks from Blender Bags?

Bursting blender bags is avoidable. The labs we spoke with have implemented protocols to completely eliminate leaks.

Each tablet has its own specificities (size, hardness, shape), so you may need different protocols to achieve your goals.

The labs we interviewed gave us some tips to eliminate bursting bags, here they are:

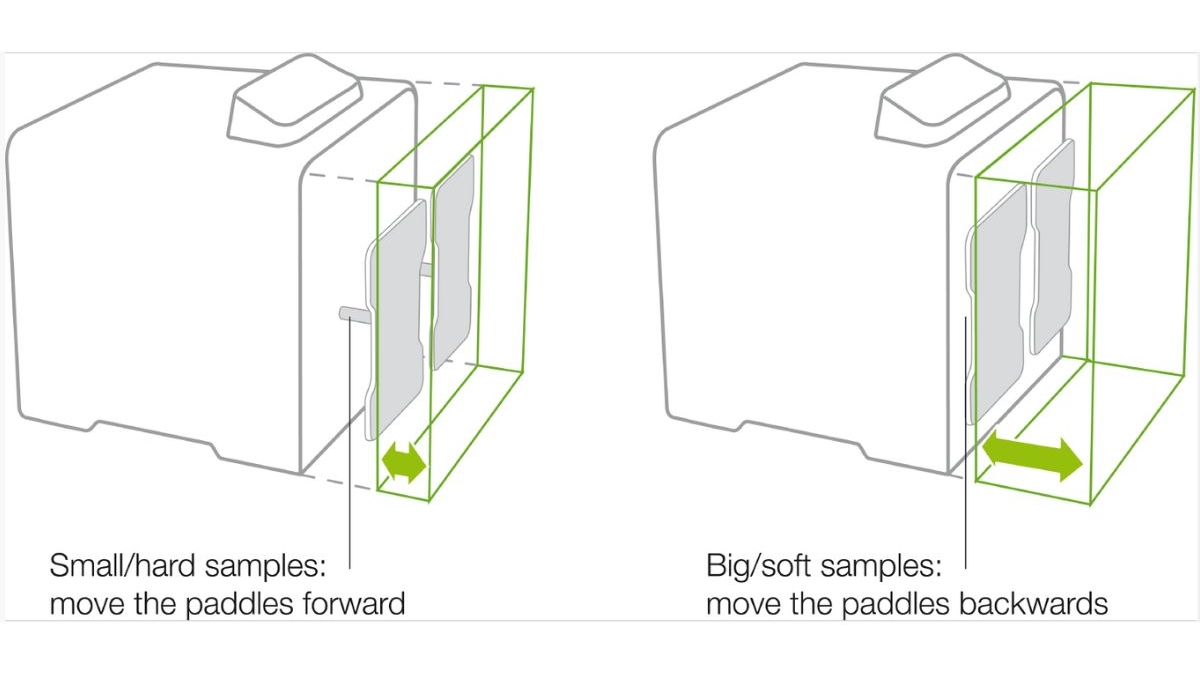

The Adjustment of the lab blender Paddles

With some brands of lab blender, the depth (and therefore the power) of the paddles can be adjusted. This eliminates a large part of the bags that leak.

The labs we interviewed use a BagMixer, the lab blender manufactured by Interscience. This model allows adjusting the paddle setting depending on the type of tablet.

It is therefore important that this adjustment can be made easily and quickly (without having to “dismantle” the lab blender).

According to the three pharmaceutical labs that use it, this model is particularly quiet (BagMixer model from Interscience).

The Adjustment of the Blender Speed

On most lab blenders, the grinding speed can be adjusted. In reality, it’s the frequency of the paddles’ beating. This adjustment also reduces the number of bags that burst.

Sequential Blending

One of the labs we interviewed, which has very (very) hard tablets, has implemented a sequential protocol.

The lab performs 3 blending sequences of 2 minutes each. The paddles are advanced at each step to reduce the tablet’s granulometry without creating sharp edges (which could pierce the bag).

A More Robust Blender Bag

The lab blender is a technology that comes from the food industry. In this field, hundreds of thousands of blending are performed each year. For cost reasons, bag suppliers have minimized their thickness (in addition, the matrices are often soft).

A standard bag will therefore not be suitable for pharmaceutical matrices.

The majority of labs we interviewed have therefore opted for more robust bags like the BagPage XR from Interscience, which is 50% thicker.

Pre-treatment of Tablets

For really complicated tablets, it’s possible to combine 2 steps:

- Tablets and diluent are agitated for 10 minutes in a sterile container with a magnetic bar.

- The sample is transferred to a bag, then grounded for 1 to 2 minutes with a paddle blender.

Blending and Heating at the Same Time

To avoid the 2 steps we just described, one of the labs we interviewed uses a lab blender that grinds and heats at the same time, the WarmMix from Interscience.

Heating softens the tablets, and the lab blender… crush them. The combination of the two is apparently very effective!

Conclusion

Grinding pharmaceutical tablets can be a real headache for QC microbiological labs.

To simplify this step, some labs have adopted a technology from food microbiology; the paddle blender.

Although this device has many qualities (quick grinding, effortless in an inexpensive sterile container), it has one identified flaw, which is the risk of bag leakages.

To limit this risk, labs must adapt their grinding protocol (excellent internship topic, right?!) by adjusting the paddles, the blending speed, using more resistant bags, or even combining several preparation steps.

Last point to consider: The noise.

A lab blender mixing a hard matrix like tablets can be very noisy. Some suppliers have developed “quiet” lab blenders, and that can prevent many nervous breakdowns in the lab!

If you have any questions about paddle blenders, feel free to ask them in the comments or contact an Interscience specialist.

We thank Interscience for giving us carte blanche on the subject. It was fascinating!

We also wish to thank Julien Jardel, Guillaume Pinon, and Jules Costa.

Leave a Reply

Want to join the discussion?Feel free to contribute!