Food Microbiology: How to choose microbiological quality control strains?

In the last few years, food microbiology laboratories have been asked to perform more and more quality control tests to verify the performances of the methods and agents they use.

To perform these QC (Quality Control) tests, food laboratories need microbial reference materials. But where can these strains be found?

A few years ago, the only alternatives to buy reference strains were the national institutes.

Today, we luckily have several reference material suppliers. And the icing on the cake, there are many different formats available: Ready-to-use freeze-dried strains, qualitative or quantitative reference materials.

But then, how do you choose the right solution for your lab?

This article will guide you through key considerations and provide tips to make an informed decision.

Summary :

- What are QC strains used for?

- 10 tips to choose a quantitative QC strain.

- How to choose a qualitative QC strain?

Best QC strains

Food & Water : The best QC Strain suppliers

We polled the SuperMicrobiologists.

Here are their favorite QC Strains

What are QC strains used for?

Quality control strains are now used for many different purposes in the food microbiology labs:

- Test the performances of the culture media (ISO 11133)

- Test the performance of other reagents (e.g.: identification system)

- Method validation (ISO 16140-3)

- Positive control

To perform those tests, you will need a wide variety of strains :

- Bacteria, yeasts and molds strains

- Calibrated or not

Even though the QC strains are still mostly prepared by the lab (from a strain bank), more laboratories are using ready-to-use strains.

The biggest reason is that preparation can be long and complicated (especially if the strain is calibrated).

So, let’s see how to choose the best QC strains.

“If a performance test goes bad, you should never ask yourself if it comes from the preparation of the microbial strain. You should only reconsider your growth medium…”

10 tips to choose a quantitative QC strain

Some QC tests required quantitative microbial preparation (e.g.:grow promotion or method validation).

You can either prepare the calibrated strain yourself starting from non calibrated microorganisms (make sure you ID them before). Or you can buy ready to use calibrated strains, which can make your life a lot easier… if you choose the right ones!

Here are the criteria to take into consideration if you want to work with the best quantitative lyophilized microbial strains:

1 – Availability of all CQ strains

Make sure the supplier can provide a wide range of strains to meet your testing needs. This will really not be funny if you need to use 2 or 3 suppliers!

Our advice: Make a list of the needed strains and verify that the supplier can provide all of them.

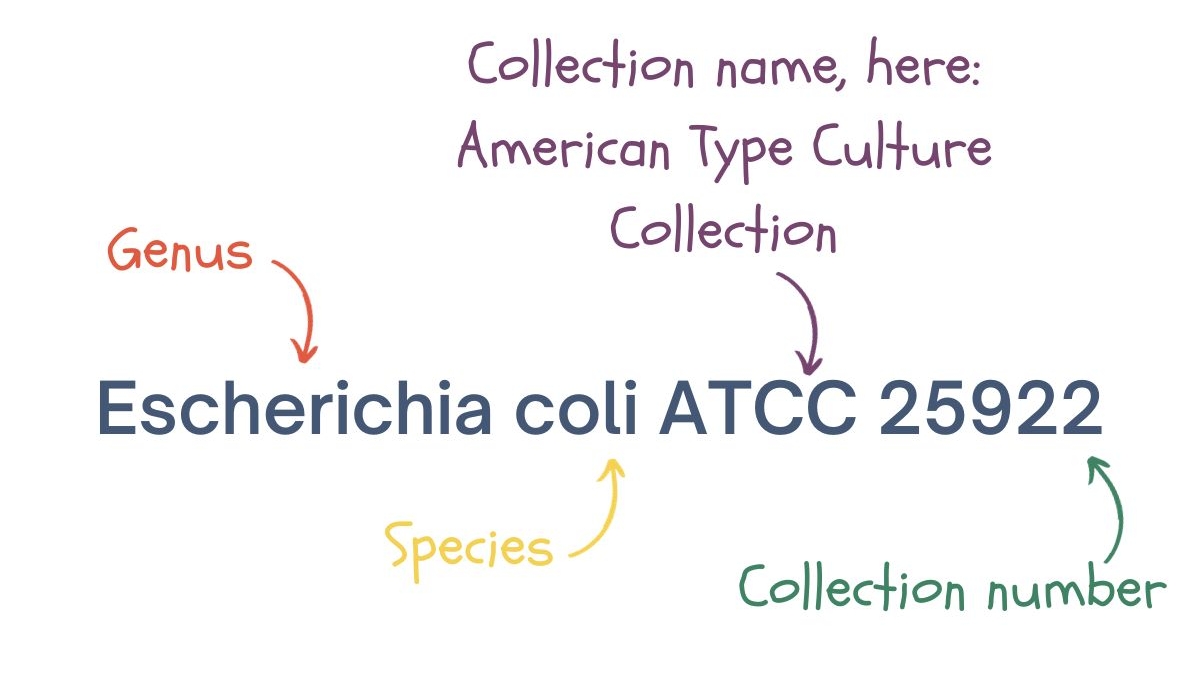

2 – Culture collection reference

It is not because they avec the same “name”, that microorganisms are the same.

For example, E.coli ATCC 25922 is not the same as E.coli ATCC 33694. They are both E.coli but they have different characteristics.

To recognize them, strains are named with a collection name and a collection number.

The most popular collection bank is ATCC (American Type Culture Collection) but it is not the only one. Almost every country has its own collection bank.

Fortunately, there are equivalences between the culture collections. The World Data Centre for Microorganisms (WDCM) website allows easy retrieval of these equivalences. For example: E.coli ATCC25922 is equivalent to E.coli DSM 1103 and E.coli NCIB 12210.

Our advice: Make a list of the QC strains you need (you will find them in the international standards or in the certificate of analysis of your suppliers), then verify that they match the ones offered by your suppliers.

3 – Purity of the QC strain

It’s rare, but it can happen with some suppliers that a strain is contaminated. To verify this point, nothing better than to discuss with other laboratories that already use the supplier, this will help you to verify its reliability.

4 – Strain concentration

Verify that the concentration offered by the supplier matches the targeted concentration for your analysis.

Usually, the aim is to inoculate with a small volume (0.1ml on an agar plate or tube and up to 1 ml for an enrichment broth). Suppliers can offer different formats, with different volumes and concentrations.

It is necessary to verify that the format is compatible with the lab’s needs and that there will not be too much loss.

5 – Ease of use

The fewer preparation steps, the better (there is less chance of mistakes)!

Depending on the suppliers, there may be preparation steps. Since you are working with living organisms, each step is important (rehydration time, dilution, incubation temperature, vortex time, etc.) and can impact the growth of the microorganism… They are sensitive little creatures!

Another point, is the format safe?

Some suppliers offer strains in “risky” packaging, such as glass ampoules. There is obviously a risk of cutting (which is not cool with a microbial reference culture) and risks of cross-contamination.

Other suppliers offer formats that are super easy to use and pose no risk to the user or the sample.

6 – Storage temperature

Depending on the supplier, lyophilized strains are stored at different temperature. They could be stored:

- At room temperature (rare)

- In the refrigerator (2-8°C)

- In the freezer (-20°C).

Depending on the space available in the lab, this storage temperature can truly be a choice criterion.

7 – Microbial strain shelflife

Calibrated QC strains can be expensive. So, it’s very frustrating to have to throw them away because they are expired.

Therefore, it’s better to favor a supplier who commits to delivering strains with the longest possible expiration date. You should target at least 6 months.

8 – Number of analyses per packaging

Depending on the supplier format, with one vial you could run from 1 to 1000 tests. You might not need all of them and unfortunately the calibrated strains are only stable a few hours.

The better you know the tests you need to perform, the best visibility you will get on its cost.

9 – Transport conditions and delivery time

Ask your supplier where its strains are made… the answer could be surprising (Australia, USA, France, Spain, …). Supply times can sometimes be long.

Is there a stock in your country? For faster delivery.

Another point: How is the temperature managed during transportation ? Cold with ice packs or room temperature?

If the transportation temperature is different from the one indicated on the box, you must ask for a validation report.

Don’t forget that transport includes from the manufacturing site to your supplier and from your supplier to your lab… you might have some surprises!

10 – Price

This is obviously a selection criterion to take into consideration. But on this point, we leave it to you to manage!

Bonus: Genetically modified strains

Some suppliers offer genetically modified strains. These strains, for example, emit fluorescent light when illuminated with a UV lamp.

They could be useful in a QC lab that uses control strains. Whenever you have a positive result (contamination) you can quickly verify if this is due to a control strain or if it is a real contamination from the product.

For pathogenic strains, this solution should really be considered.

How to choose a qualitative QC strain?

Qualitative strains are generally used to stock your laboratory’s culture collection (freezer -20 to -80°C). Almost all the above criteria are applicable. We would only add this one:

Number of passages

The strains stored in culture collections are generally subcultured a certain number of times.

With each subculture, the strain undergoes mutations that can cause it to lose certain important characteristics. These mutations can eventually have a negative impact with your detection methods (PCR or chromogenic media, for example).

Some suppliers offer microbial strains with 1, 2, or 4 passages from the reference strain.

For storage in a culture collection, strains with 1 or 2 passages maximum are generally preferred.

Conclusion

Choosing your microbial strains isn’t just science; it’s an art.

With a wider range of suppliers offering various strains and formats, laboratories have more options than ever.

Arm yourself with the above checklist, keep your lab coat buttoned up and go challenge your suppliers by asking them as many questions as possible.

And most importantly… Let us know in the comments which one you choose.

ISO 11133 : Microbiology of food, animal feed and water : Preparation, production, storage and performance testing of culture media.

ISO 16140-3 : Microbiology of the food chain, Method validation. Part 3: Protocol for the verification of reference methods and validated alternative methods in a single laboratory.

a.

Leave a Reply

Want to join the discussion?Feel free to contribute!