How does a class 2 Biological Safety Cabinet (BSC) work?

Today, most microbiology laboratories use a class II Biological Safety Cabinet (BSC). But how many microbiologists really know how this tool works?

Understanding the operating principle of a BSC allows for better comprehension and thus avoiding handling errors that could lead to contamination.

By the end of this article, the BSC will have no more secrets for you!

The

Best

BSC

Discover the best BSCs for microbiology

We polled the SuperMicrobiologists.

Here are their favorite brands of BSC

What is the role of a class 2 BSC?

The class 2 biological safety cabinet (there are 3 types) has 2 objectives. It is designed to protect:

- The laboratory environment and the handler from contamination coming from the sample.

- The sample from contamination coming from the handler and the environment.

Composition of a class II BSC

Regardless of the brand and model, the essential components of a BSC are always the same. But there still needs to be agreement on the names of these components… To help you, here is the glossary of the Biological Safety Cabinet:

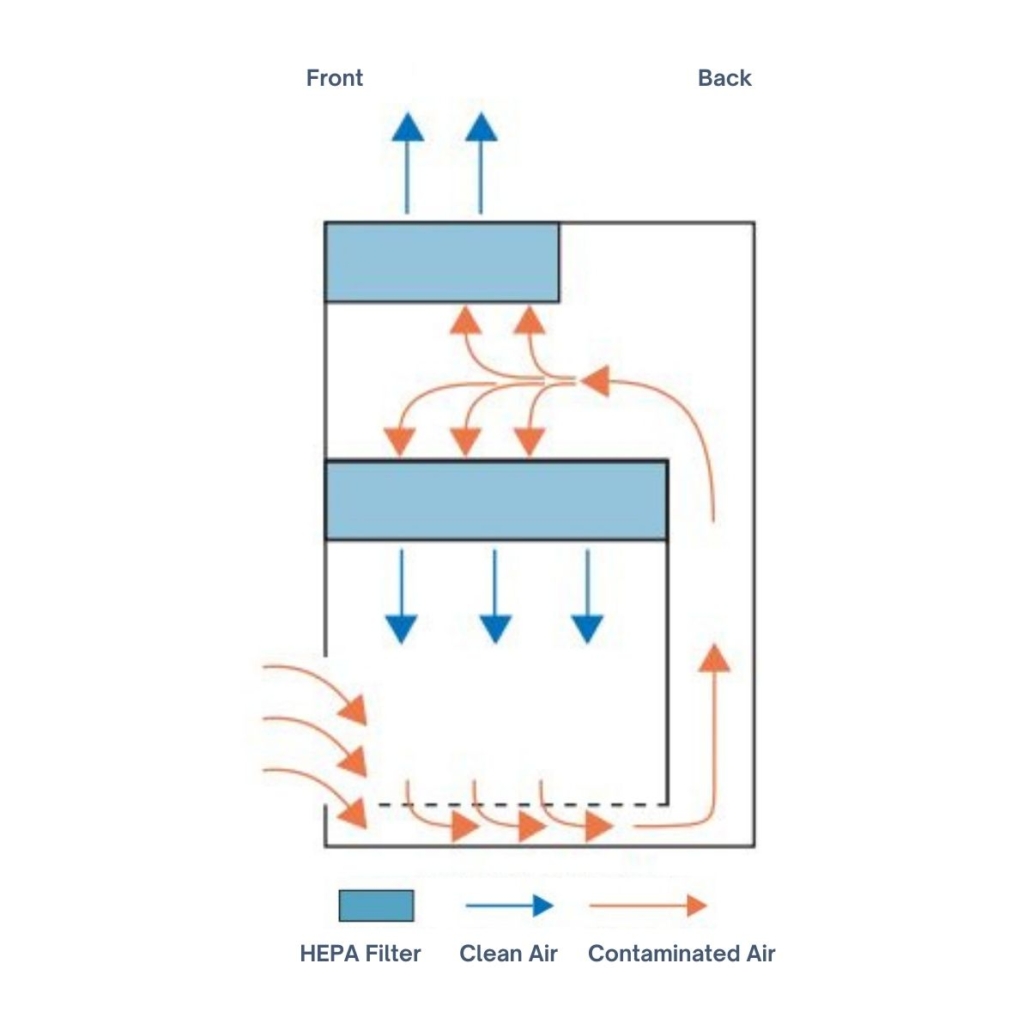

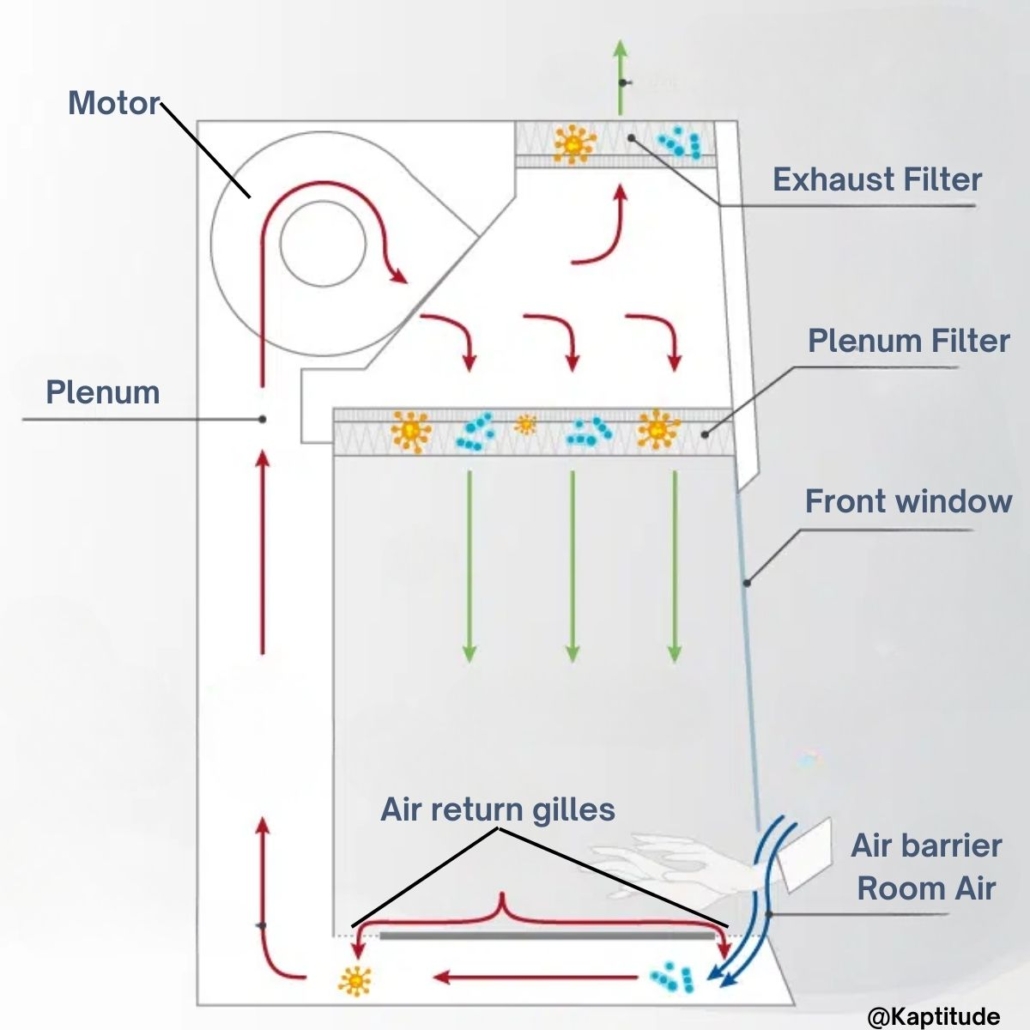

- The air barrier: This is an immaterial element that is created by drawing air from the laboratory towards the underside of the BSC’s work surface. This air barrier is actually an air curtain that protects the handler from contamination.

- The air return grilles: These grilles are located around the work surface (in front and on the sides). They allow the recovery of descending and incoming air.

- The plenum: Normally, you never see this… except when changing the filters. The plenum is located in the upper part of the BSC. It is a hermetic chamber that stores “contaminated” air.

- The motor: Also called blower or fan. It creates the air barrier (by suction) and pushes the contaminated air through the 2 filters (extraction and blowing). It is what allows for a constant laminar flow inside the BSC. Depending on the model, there may be 1 or 2 motors.

- The exhaust filter: This is the filter through which air is expelled into the laboratory (or outside the building). It prevents contaminating the lab environment by keeping contaminants inside the plenum. There are several types of filters (HEPA, ULPA).

- The plenum filter: This is the filter through which air is injected into the BSC’s workspace. It protects the sample from contamination.

Operating principle of a class 2 BSC

Even though a biological safety cabinet may seem complicated, its operating principle is actually quite simple.

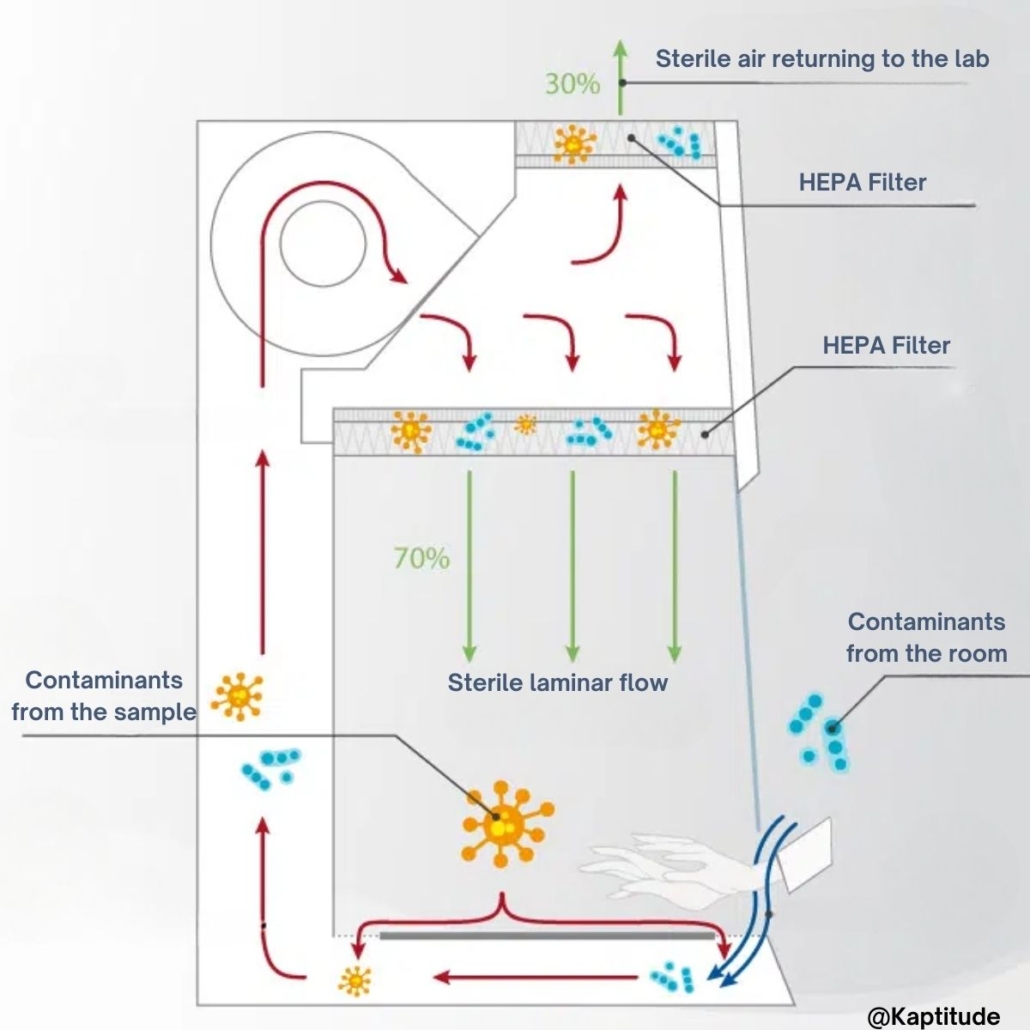

To protect the microbiologist, the BSC continuously draws in 30% of air at the level of the air barrier. This “contaminated” air, passing under the work surface (without coming into contact with the sample), is joined by the air from the laminar flow and then they both move into the plenum.

In the plenum:

- 30% of the air is expelled into the laboratory. This air passes through a filter that sterilizes it, thus protecting the environment. This air is expelled towards the laboratory’s ceiling, so it is important to have a bit of height, 20-30cm, otherwise the flow is disrupted, and the BSC goes into alarm.

- 70% of the remaining air passes through the blowing filter to be reinjected into the workspace as a sterile laminar flow… and the cycle repeats!

Filters used in a BSC

Inside a biological safety cabinet, there are 2 filters: the plenum filter and the exhaust filter.

There are various types of filters, with more or less significant “porosity,” such as HEPA (High Efficiency Particulate Air) or ULPA (Ultra Low Penetration Air) filters.

Did You Know?

When starting up a BSC, before it can be used, it generally requires a preheating duration. This preheating time allows, among other things, to recycle all the air in the BSC, to bring the fan up to full speed, but also and especially to electrostatically charge the HEPA/ULPA filters. These filters reach their maximum efficiency once charged.

These filters are air filtration technologies designed to filter particles larger than 0.3 microns. For reference, a bacteria measures between 0.5 to 3 microns.

| Filter | HEPA | ULPA |

|---|---|---|

| Efficiency | 99,99% | 99,999% |

| 1 million spores | 10 escape | 1 escape |

| Work Zone | ISO 5-4 | ISO 3 |

A vast majority of BSCs found in our laboratories are equipped with HEPA H14 filters. Generally, the ULPA filter is an option.

How often should BSC filters be replaced?

That’s the million-dollar question… the answer is “It depends”!

The frequency of changing the filters depends on how dirty they get. The more particles there are suspended in your lab air or in your samples, the more the filters will clog and eventually become blocked. That’s when the BSC goes into alarm.

To give you a general idea, in microbiology laboratories, BSC filters are typically replaced every 4 to 7 years (it’s a pretty large range).

However, a dirty filter can impact the functioning of the BSC. To maintain a constant laminar flow, the motor may need to blow harder, which means the BSC will make more noise and wear out faster.

Conclusion about BSC operation

Now that we know how a BSC works, we understand that if we want to protect the sample, the environment, and the microbiologist, we need to:

- Disturb the air barrier as little as possible.

- Not obstruct the air return grilles.

- Clean thoroughly everything that enters the BSC.

- Keep the lab clean to avoid sending too much dust into the air barrier (which can clog the filter).

And you, how often do you replace your filters?

Leave a Reply

Want to join the discussion?Feel free to contribute!