Microbiology: How to choose a class 2 Biological Safety Cabinet?

If you need to purchase a Biological Safety Cabinet in the coming weeks, this article is for you!

It’s true that we don’t buy a BSC (Biological Safety Cabinet) every day… nor even every year (a good BSC can last 20 years). So, when it’s time to buy a new BSC, it can be a bit confusing… But that’s where SuperMicrobiologists come in.

In this article, we list the main criteria to consider when purchasing a BSC.

Contents:

- Technical features of the BSC

- Usage features of the BSC

- How to choose the BSC accessories?

- Installation, maintenance, and service of the BSC

- How to trust your BSC supplier?

The

Best

BSC

Discover the best BSCs for microbiology

We polled the SuperMicrobiologists.

Here are their favorite brands of BSC

What is a class 2 Biological Safety Cabinet?

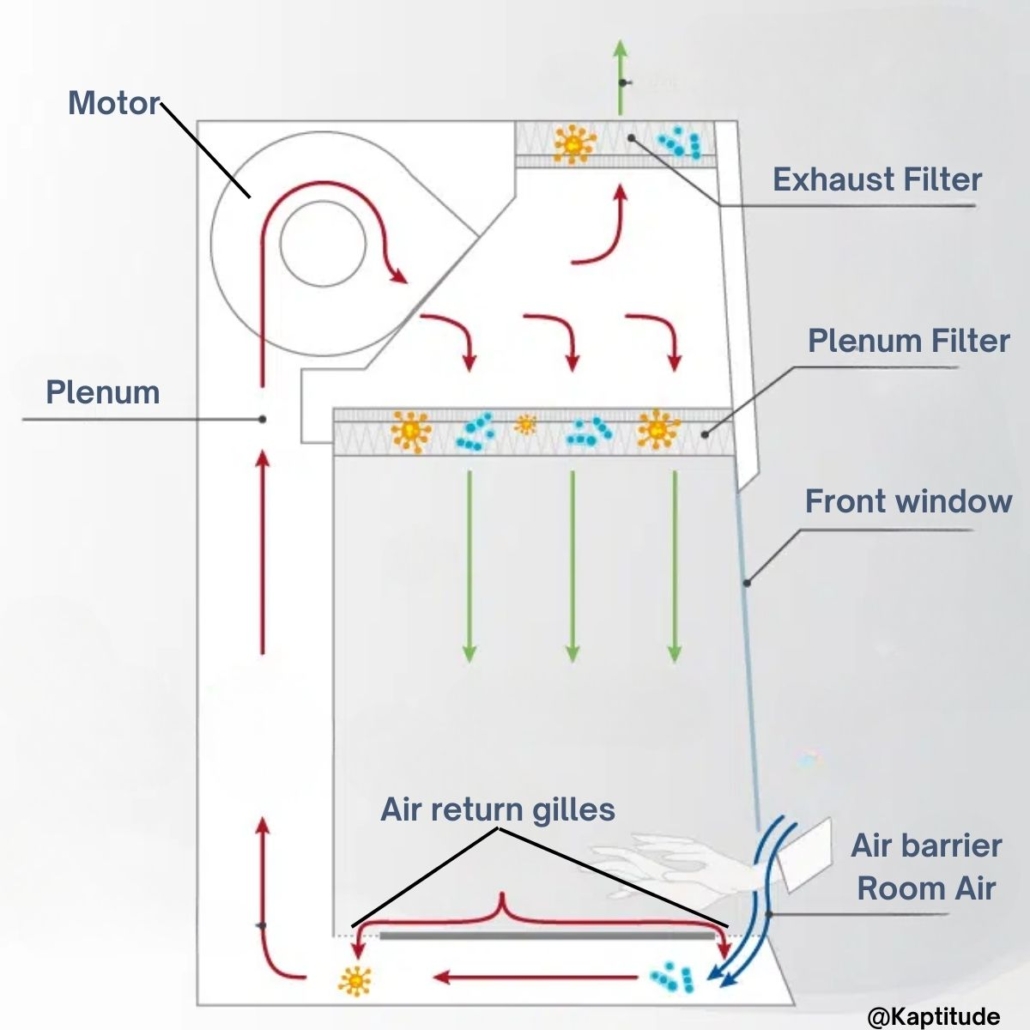

A class II biosafety cabinet is a laboratory device that allows safe work with pathogenic microorganisms.

It protects the microbiologist handling it, the sample, and the laboratory environment. If you want to know everything about how a BSC works, go read this article.

1 – Technical features of the BSC

Size of the Biological Safety Cabinet

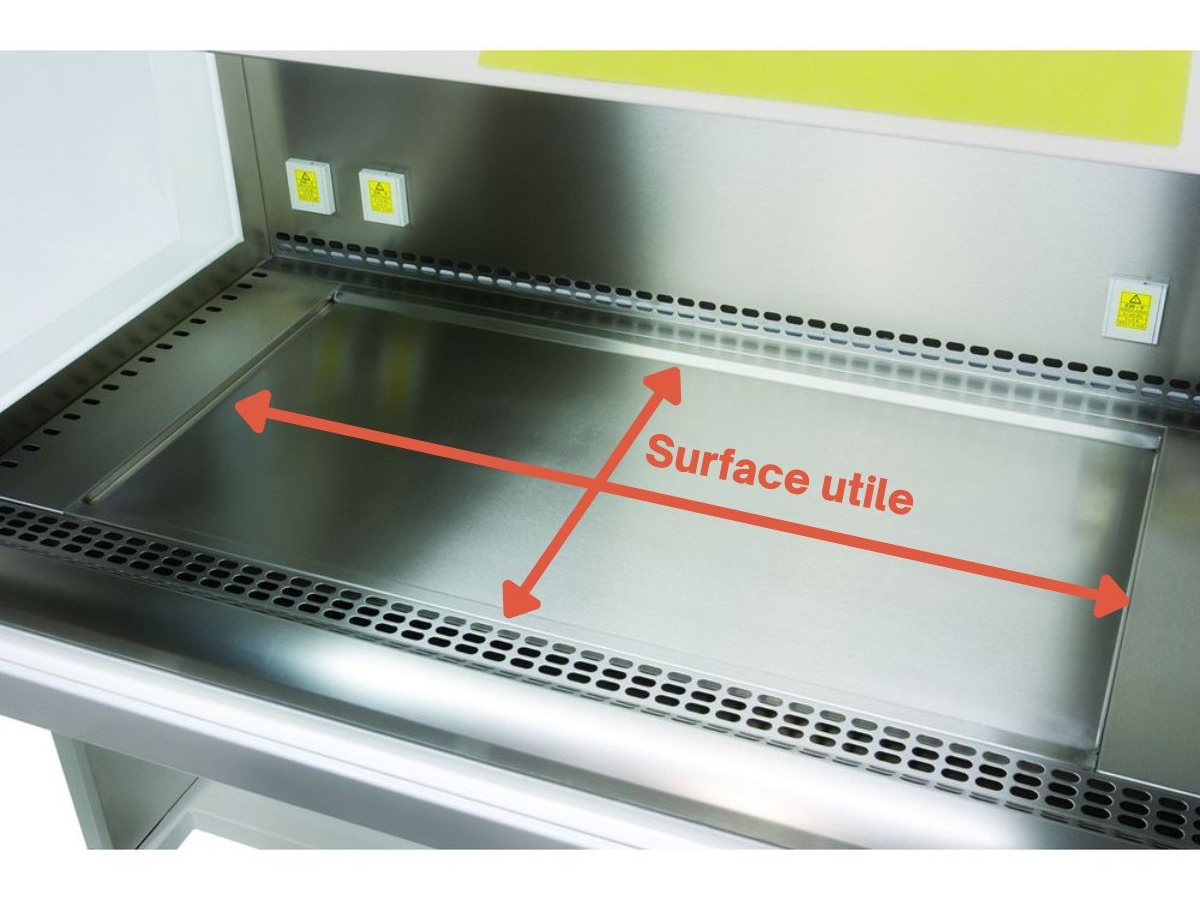

There are 4 standard sizes of BSCs: 90cm (6 feet), 120cm (the most common) (9 feet), 150cm (12 feet), and 180cm (15 feet).

Generally, the size is chosen based on the space available in the laboratory. It’s also important to consider the type of manipulation and the equipment you will use in the BSC.

It’s important to ask the supplier about the useful work surface, measured in m2. Two 120cm BSCs might not have the same work surface.

Many labs opt for the 180cm, thinking they can manipulate with 2 people at the same time in the BSC… but this is really not recommended (the flow would be too disturbed = risk of contamination).

Our advice: Don’t buy too big if you don’t need it. The larger the BSC, the more electricity it consumes, and the more expensive maintenance and filter replacement will be.

Filter choice for a BSC

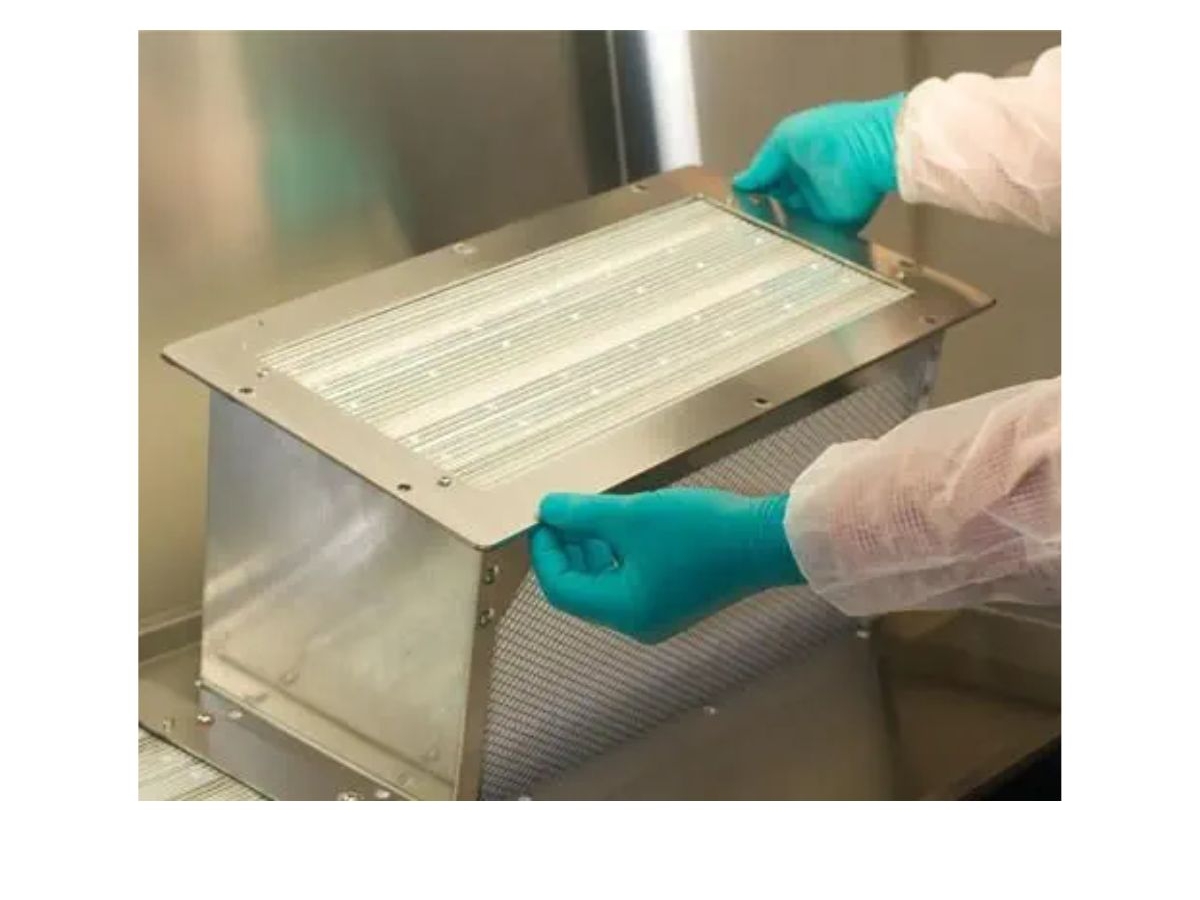

Each BSC uses 2 filters (extraction and blowing). There are several types of HEPA and ULPA filters, but today the majority (if not all) of BSCs use H14 HEPA filters.

Our advice: It’s important that the BSC uses “standard” filters. Being able to source filters from multiple suppliers ensures filter availability and also a lower price.

Materials choice for a BSC

The workspace of a BSC can be made of several materials, mainly found in the work tray, retention tray (under the work tray), side walls, and back wall.

Generally, you have a choice between these 4 materials:

- Painted steel

- 304 (L*) stainless steel

- 316 (L*) stainless steel

- Glass

Your choice will depend on the activity you have with your BSC (frequency of use, type of product, frequency and type of disinfection). Of course, price is also a factor.

*”L” means “Low carbon”. This doesn’t change the quality of the stainless steel. It increases resistance during hot welding.

Painted steel

Lighter and cheaper than stainless steel, but less resistant. Usually found on surfaces that are less stressed (under the work tray, back and side walls). Recommended for non-intensive uses and non-aggressive disinfections.

304 (L) stainless steel

More corrosion-resistant than painted steel, usually used for the work tray and walls.

316 (L) stainless steel

Even more corrosion-resistant than 304, but more expensive. Some brands offer a 316 stainless steel work tray. Optionally, a BSC can be entirely made of 316 L, especially when regularly subjected to hydrogen peroxide (+ peracetic acid) disinfections.

Glass

Used only for side walls. Provides natural light to the worktop, making it more pleasant for the microbiologist.

Our advice: Choosing the right material might be more expensive initially, but it will last much longer. Take time to discuss your use of the BSC with manufacturers.

Going further with stainless steel: Stainless steel is not perfectly smooth; it has microscopic peaks and valleys. The more asperities, the more liquids can lodge there, increasing corrosion. To limit these asperities, stainless steels are polished. Ask the supplier about the type of polishing; 200 (coarse polishing), 1200 (fine polishing, mirror-like).

1 or 2 motor/blower?

Motors, also called blowers or fans, create the airflow in the BSC. Having 1 or 2 fans doesn’t change the quality of protection provided by the BSC.

1 motor

Manages the 3 flows (inlet with guard vein, top extraction, and downward flow in the work area) alone. It’s cheaper than 2, but a bit noisier and more complicated for service.

2 motors

One motor handles extraction and air intake (from the front glass), the other blowing in the work area. This option is a bit more expensive, but as the motors work less, they are quieter and have a longer lifespan (in theory). It’s also easier to adjust for service. If you opt for external extraction, you must choose 2 fan motors.

There are several motor technologies. As of today, EC (Electronically Commutated) are the quietest and least energy-consuming.

Display and control

There are several types of displays and controls. Like cars, there are models with buttons, small screens, or touch screens. Our only advice is to check the ease of use of the interface (preferably in your language). For this, you need to… test.

Electric consumption of the BSC

An increasingly important criterion for labs. The consumption of a BSC is measured in W/h (watt per hour). To compare, measure identical things, so look for consumption during operation.

The difference in energy saving comes from the motors. Currently, the least energy-consuming are EC motors in DC.

To reduce consumption, some suppliers offer a “standby” mode (when the BSC is not used… during breaks, for example) that reduces flows while maintaining optimal protection.

Noise level of the BSC

If you spend several hours a day in your BSC, you know how important this criterion is. The EN 12469 standard requires a noise level below 65 dB, but not all noises are equal. A 45 dB can be painful to the ears and a 65 dB much softer. Again, the ideal is to be able to test in a showroom or at another user’s place.

EC motors tend to be quieter.

Self-regulation of the BSC

Some BSCs can auto-regulate the power of the motors. When a filter becomes clogged, instead of going into alarm, the BSC maintains the flow speed by increasing the power of the motors. This option is very practical and delays the intervention of technical service and the replacement of filters (up to a certain point).

Ideally, speed measurements are done with 2 anemometers (for extraction and blowing).

BSC finishing touches

By finishes, we mean everything that will constitute the welds and joints.

To facilitate cleaning and disinfection of the BSC, there should be a minimum of right angles, nooks, and burrs at the welds.

Our advice: If you have the opportunity, ask to look at the angles and welds under the worktray.

Prefilter and other filters of the BSC

Depending on what you do in the BSC, you may need other filters (in addition to HEPA filters).

If you handle powders (cosmetics or milk powder), you will need a prefilter, otherwise, you’re heading for disaster. Powders will clog your HEPA filters in record time, and you will have to replace them every 6 months instead of every 6 years!

If you handle “chemical” products, you may need to add a charcoal filter or external extraction.

In any case, it’s very important to explain your applications to your suppliers.

Certifications of the BSC

There are several types of certifications: NF, TÜV, NSF, etc. The question is whether you need your BSC to be certified? If not (which is often the case), make sure the manufacturer commits to taking back the BSC if it does not pass the initial qualification.

2 – Usage features of the BSC

Height of the glass opening

The EN12469 standard requires that the opening be between 16 and 25 cm. For comfortable handling, the larger the opening, the more freedom of movement the microbiologist has. 20 cm is good, 25 cm is even better!

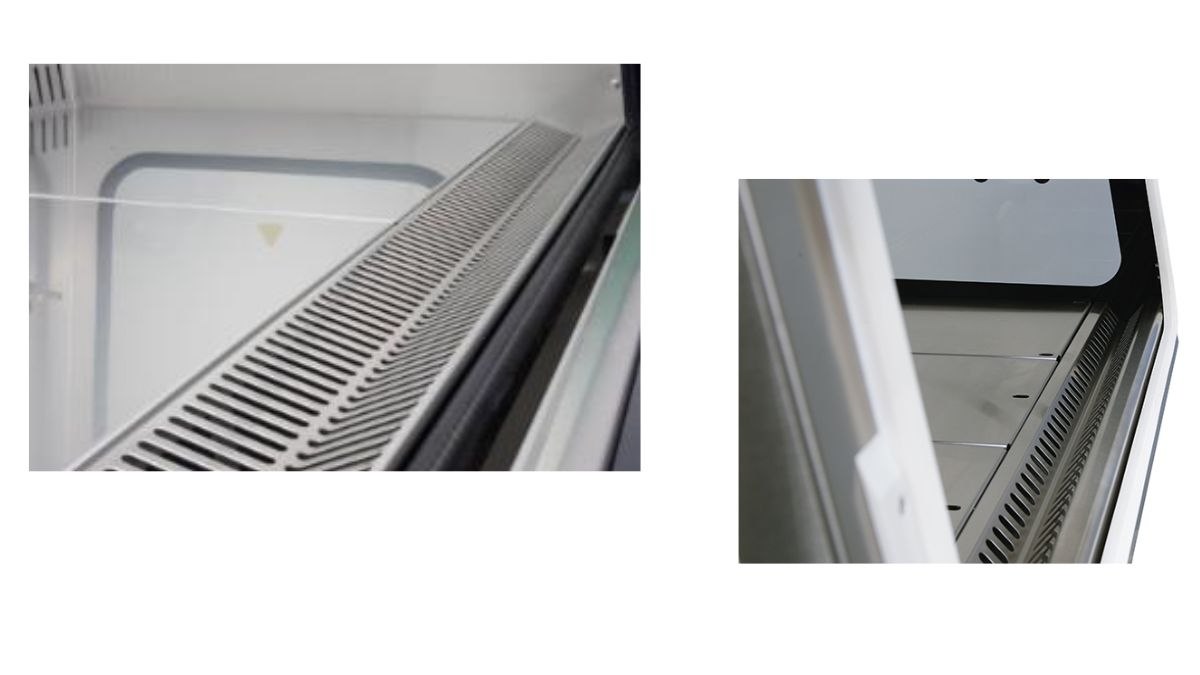

Air intake grille

Since recommendations suggest manipulating 10 cm from the air intake grille, the narrower the grille, the less the microbiologist has to stretch their arms to manipulate, and therefore it’s more comfortable.

Inclination of the glass

For better visibility inside the BSC (to avoid reflections), some BSC manufacturers offer a window with an angle. The “ideal” angle for BSC ergonomics is between 7 and 10°.

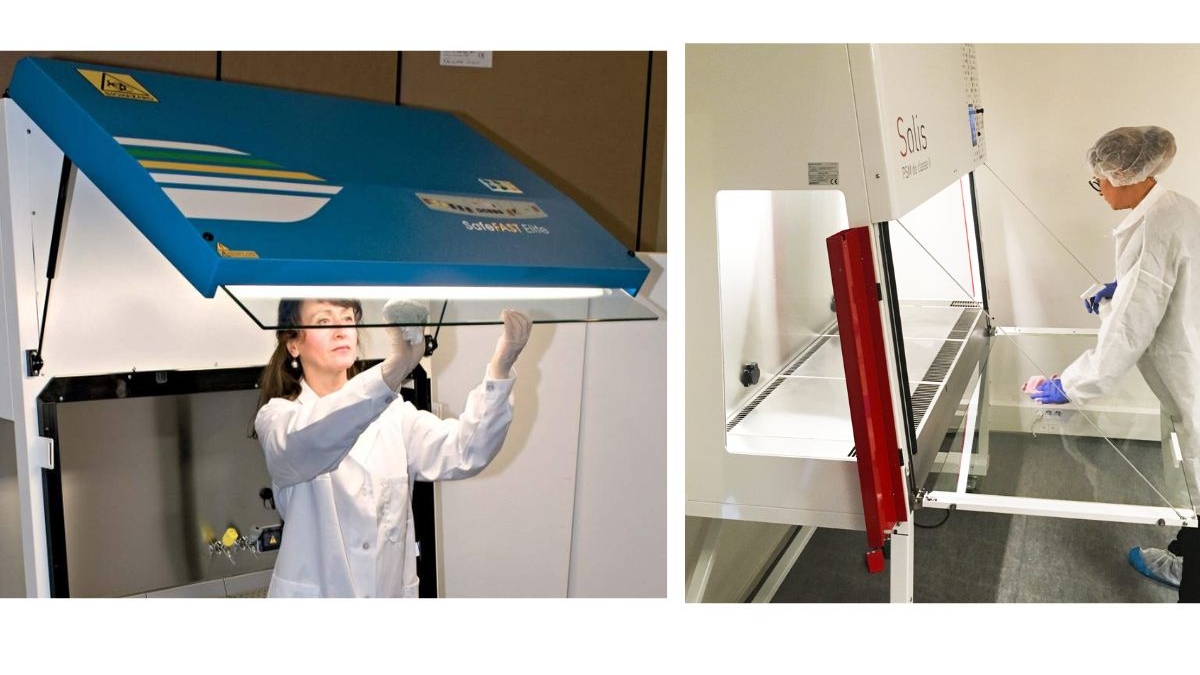

Glass opening: manual or automatic

Often a question of price… but sometimes of conviction.

A manual window will be cheaper, less comfortable (especially for large BSCs). But it does not break down (normally!).

An automatic window will be a bit more expensive, but more comfortable (especially for larger models).

UV “disinfection”

UV is used in the BSC to disinfect surfaces… that’s the theory, because in practice its effectiveness seems to be minimal. But since everyone has always used it, everyone wants it… and so manufacturers offer UV disinfection.

It is a surface disinfection, so the UV tube must be as close as possible to the surfaces to be decontaminated. For this, there are several strategies among manufacturers (magnetized tubes that can be moved, tubes above the work tray, tubes integrated into the corners, …).

We have a quite firm opinion on the subject… so we leave you to choose according to your conscience. But don’t forget that for optimal disinfection, you must first clean well (elbow grease is not sold in 10-liter cans!).

Cleaning of the front glass

The front glass is very easy to clean from the outside. But how to clean the inside? Do we contort in all directions?

No, manufacturers have thought of everything and generally the window can open to facilitate cleaning. There are many different ways of opening and cleaning it, but not all are that easy. It’s up to you to assess what seems acceptable.

“Cleaning the window is good, cleaning the joints is better”.

Bob M.

Our advice: If the opening of the window is too restrictive, you will never do it and if you never do it, you will have… contaminations.

3 – How to choose the BSC accessories?

Work tray

There are also plenty of options here!

Perforated work tray or solid work tray

- Perforated work tray: The laminar flow will be more “qualitative” (there are fewer obstacles to the flow), but it’s more complicated to clean.

- Solid work tray: This is the most common. The flow is a bit less “qualitative,” but it easily passes qualifications. It is easier to clean, and there is no risk of things falling under the worktray (especially liquids).

Monobloc or segmented work tray

- Segmented work tray is easier to remove (for access to the retention tray), less heavy, and autoclavable. However, dirt and liquid can slip between 2 plans.

- Monobloc work tray is heavier, less easy to remove (especially for a large BSC). However, it is easier to clean when not disassembled (a smooth surface).

Armrest

The armrest has 2 purposes: to prevent the forearms from blocking the air intake grille (disturbing the flow) and improving ergonomics for the microbiologist.

There are 2 types of armrests:

- Along the length: The armrest is outside, the operator can move along the entire length without needing to move the armrest.

- Individual: Composed of 2 armrests (one for each) that are placed above the air intake grille. It can be moved, the spacing adjusted, and it can be dismantled for cleaning.

Electrical sockets / pipes and cables ports

Our only advice is to anticipate your needs because it’s very complicated to add a cable port or socket after the BSC leaves the factory.

“Stop wipe” grille

It’s a grille located under the work tray that prevents objects (micropipette tips, wipe) from being sucked into the plenum. When this happens, it often requires a technical service intervention, with total decontamination of the plenum… an expensive intervention.

Our advice: If this grille is optional, we strongly recommend taking it; it’s a good investment!

BSC base stand choice

Placing your BSC on a laboratory bench is a doubly bad idea. First, because it’s not ergonomically suited for that purpose. And then, because a laboratory bench is expensive, it would be a shame to use it just to place a BSC on it.

A BSC should be placed on a base stand, and the only thing left to do is to choose which one.

Often, these stands are adjustable. There are two standard heights: 70 and 90 cm (this can vary slightly depending on the brand).

The choice of height must be made at the time of installation (after that, it’s too heavy to change). This choice should be based on the height of the microbiologists and the type of seat (chair or stool) they use.

There are also electrically adjustable stands. They are much more expensive, but so practical. Depending on the height of the microbiologist, you can adjust the height in just a few seconds.

Our advice: No, you should not equip your entire lab with electric stands (even though it’s not such a bad idea!), but if you can have at least one, it would be good. It would allow everyone to use this BSC (both tall and short people) while avoiding Musculoskeletal Disorders (MSDs).

Base stand feet

Wheels: No, wheels do not allow you to move the BSC like a shopping cart (in fact, after each movement of the BSC, it must be re-qualified). The wheels allow you to move the BSC a few centimeters during service interventions or a “deep” cleaning of the lab.

Leveling feet: These feet mounted on screws allow you to compensate for an uneven floor. However, to move the BSC with these feet, you need to call professional movers!

4 – Installation, maintenance, and service of the BSC

BSC delivery

A BSC is heavy, bulky, and fragile at the same time. Needless to say, its installation is complicated and can involve some (bad) surprises!

But this problem has a silver lining, it will help you answer the famous question, “what’s the difference between a good and a bad BSC salesperson?”

A good salesperson will come to your site and ask you to follow the path the BSC will take from the unloading area to the installation site in the laboratory. They will check the widths of doors, the dimensions of the elevator, the width of the stairs. We’ve seen plenty of BSCs that didn’t make it to the lab!

Our advice: You can cut out a cardboard template the size of the BSC’s footprint (width x depth) to ensure it fits everywhere.

BSC installation in the lab

Another important point for which the supplier’s advice is fundamental.

Do not place a BSC next to a door, a passageway, a window, in a corner, near a ventilation or air conditioning system. All this to avoid disturbing the airflow. Remember that the airflow in a BSC is fragile (0.4m/s = 1.4 km/h), so care must be taken to avoid turbulence.

Once the location is found, check the ceiling height. There must be between 20 and 30 cm above the BSC to not disturb the extraction flow (otherwise, the BSC will always go into alarm).

Some BSC brands are less tall than others.

BSC initial qualification

Just after installation, to check that the BSC is functioning correctly, you need to perform the BSC’s initial qualification.

Is this service included with the sale of the BSC?

Who performs this maintenance (the supplier or a service provider)?

A service provider avoids having the supplier be both judge and party.

And if the BSC fails the control, what happens?

This subject must absolutely be discussed with the supplier before buying the BSC.

After-sales service of the BSC

The crux of the matter is knowing who will take care of repairing the BSC in case of a breakdown.

How quickly can they intervene, and is it a person from the manufacturer, a distributor, or a service provider?

You also need to inquire about the availability of spare parts.

With some suppliers, you have to wait several weeks (or even months… without being able to use the BSC!).

You can ask them where the spare parts are stored (in their warehouse, in your country, or at the other end of the world). You can also ask them to make written commitments regarding the timeframes for the availability of intervention and parts.

5 – Communicate with fellow BSC users

Do not hesitate to discuss with other microbiologists to find out if they are satisfied with their BSC. Buying a product based on a peer’s recommendation is the best guarantee of satisfaction.

6 – How to trust your BSC supplier?

There is one last argument, which is the same for all technologies, and that is… the trust you have in your supplier!

This argument may seem subjective, but it can be based on tangible criteria, such as:

- Is it easy to reach them by phone?

- Do you get directly through to them or to a voice server?

- Have you already worked with them? If not, you should inquire with another lab (on LinkedIn for example).

- Are they responsive and quick to provide a solution in case of a problem?

In order to give you the best advice, the supplier should ask you at least the following questions:

- What type of product will you be handling in the BSC? (choice of materials, size, types of filters, and options).

- How often will you use the BSC? (once a week or 8 hours a day every day).

- What type of disinfection will you be using? (choice of materials).

In the case of BSC, sales must visit your lab before sending you a quote (to quote for the delivery, to see the space in the lab, the lab height, etc…).

Conclusion about BSC

In conclusion, choosing the right Biological Safety Cabinet requires careful consideration of various factors including size, filter type, material, and ergonomic design.

Always consult with experts and fellow users to ensure a wise investment, prioritizing safety, efficiency, and long-term reliability in your laboratory environment.

And then, let us know in the comments which one you picked-up!

Leave a Reply

Want to join the discussion?Feel free to contribute!