Metrology and Maintenance of a class 2 Biological Safety Cabinet (BSC)

Is your biological safety cabinet (BSC) functioning properly? It means, does it really protect the laboratory environment, the microbiologist, and the sample.

To ensure this, it must be regularly tested, and if the filters are damaged or clogged, they must be replaced.

We interviewed two specialists in BSC maintenance to better understand the physical tests performed during their interventions.

Summary:

The

Best

BSC

Discover the best BSCs for microbiology

We polled the SuperMicrobiologists.

Here are their favorite brands of BSC

Metrology of a Biological Safety Cabinet

The EN 124691 and NSF/ANSI 492 standard encourage the users of Microbiological Safety Cabinet to regularly perform metrology of their Class II BSCs (Biosafety Cabinet). In some cases the term “maintenance” is used.

This metrology must be done at installation, when the BSC is moved or at least once a year.It verifies the effectiveness of the BSC (protection of the operator, the product, and the environment).

Here are the different physical tests conducted during the metrology.

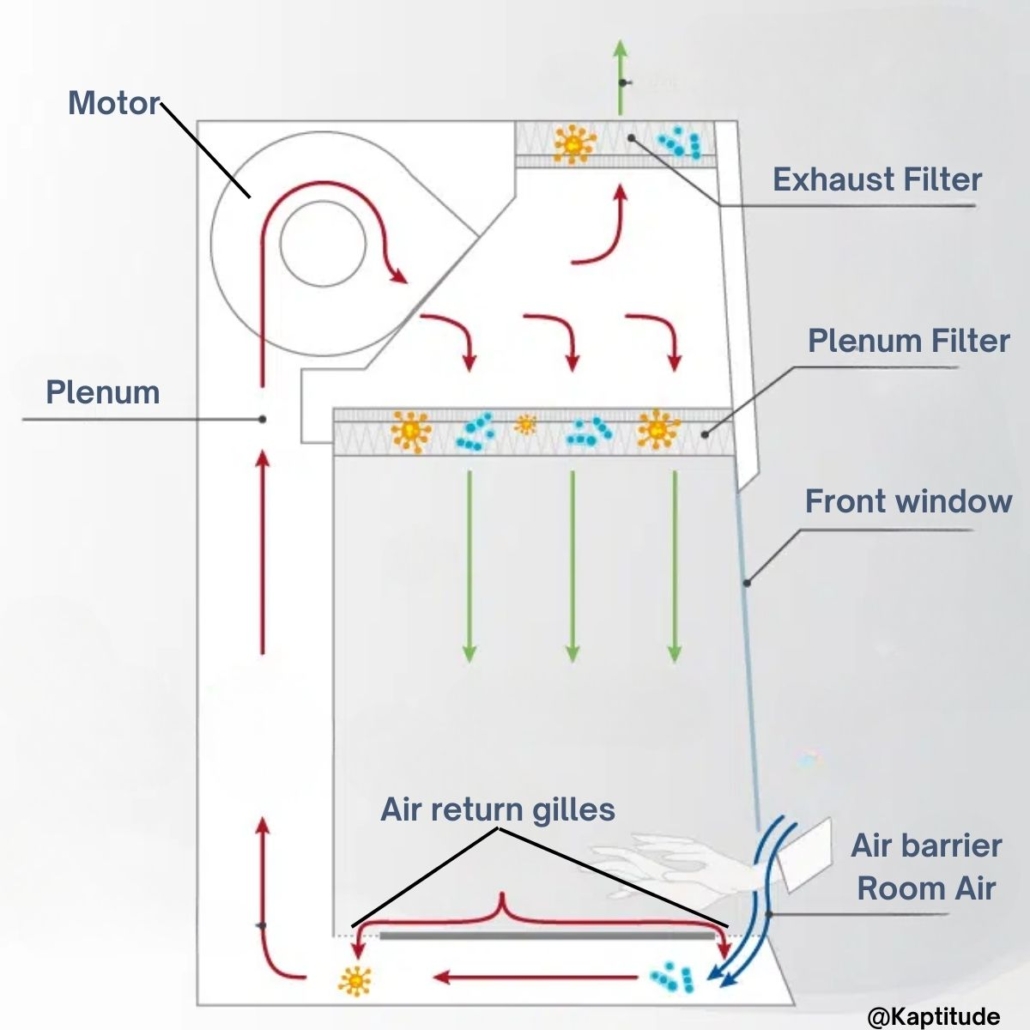

Verification of the down flow velocity and the laminarity

The measurement is taken at 8 points, under the plenum HEPA filter (inside the working area), with an anemometer. Then, the average velocity is calculated.

The NF12469 standard requires that the down flow velocity under the filter must be between 0.25 and 0.5 m/s (between 0.36 and 0.54 m/s according to the pharma reference).

Laminarity is validated if no speed varies by more than 20% from the average.

=> This test validates the protection of the manipulation/product

Verification of the inflow velocity

This velocity is determined by measuring the extraction flow velocity (exhaust filter), which must be 0,51 m/s (NSF/ANSI 49-2002) or higher than 0.4 m/s (EN12469).

As a reminder, the BSC draws in 30% of air through the front aperture and expels 30% through the extraction filter. Therefore, the extraction flow is equal to the incoming air flow.

=> This test validates the protection of the operator

Smoke Test

This test visually checks the effectiveness of the front aperture, as well as the laminarity and absence of dead zones in the descending air.

Smoke is placed at several points under the filter, and the laminarity of the flow is visually checked. If the filter is blocked or damaged at any point, it will be immediately visible (the smoke will go to the sides or rise up).

The same test is done at the front aperture level. Smoke is produced inside at the level of the glass above the front aperture (air barrier), and the flow towards the front air intake grille is observed.

Integrity test or Emery test (formerly D.O.P. test)

This test verifies that the H14 filter stops at least 99.995% of particles larger than 0.3 microns. This test is performed at the output of the two filters (plenum and exhaust).

A known number of particles (>0.3 microns) is injected into the BSC. Then, measurements are taken after the filters to ensure that they are correctly stopping the particles.

Exhaust Filter => This test validates environmental protection

Plenum Filter => This test validates the protection of the manipulation/product

Comfort Parameters Test

These tests are not offered by all service providers. Temperature, acoustic pressure, and light intensity inside the BSC are measured.

Replacing filters in a BSC

There is no preventive maintenance to be done on a BSC… except to disinfect it after each use (and to talk to it nicely, of course!).

The only maintenance to be done will be curative, in case of alarm, failure, or…clogged filter. In this case, it will need to be replaced.

Before replacing a filter, you can increase the power of the fan (blower). This will blow harder to maintain an “acceptable” laminar flow velocity. This allows postponing the replacement of filters, but be careful,the BSC will consume more electricity, the fans will make more noise and will wear out faster.

Some BSCs automatically regulate the speed of the fans when the filters become clogged.

If routine maintenance shows that the filters are out of order, then they must be replaced. Before proceeding with this replacement, the plenum must be decontaminated (all contaminants end up in the plenum).

To decontaminate the BSC, a device (nebulizer) is used to diffuse an H2O2 solution (+ peracetic acid optional). The BSC operates in recycling mode during the product’s action time, meaning the extraction is connected with the front opening.

Once decontamination is done, the technician can safely replace the two filters.

How often to replace the filters of a BSC?

It all depends on the room in which the biological safety cabinet is installed. If the room is dusty, then the filter will clog much more quickly.

If you handle powders in the BSC, again the filters will clog more quickly. For powders, it is better to use a BSC equipped with a pre-filter.

But generally, HEPA filters need to be replaced every 4 to 7 years.

How to extend the BSC lifetime?

To increase the life of the filters, the BSC must be located in a clean room (with as few particles as possible).

You need to select a good BSC at the time of purchase (it means a BSC that support well the filters replacement… it is not the case for all) and perform at least the metrology as defined in the standard.

If you take a good care of it, you will be able to keep your BSC for more than 15 years in your lab!

Conclusion

Ensuring the optimal performance and safety of a Class 2 Biological Safety Cabinet (BSC) is crucial in a microbiology laboratory setting.

Regular metrology and maintenance, guided by the standards of EN 12469 and NSF49, are essential to verify the effectiveness and safety of the BSC for the operator, the environment, and the sample.

Adherence to these standards through routine physical tests, such as verifying downflow and inflow velocity, conducting smoke tests, and performing integrity tests, assures the BSC’s proper functioning.

While filter replacements are only necessary when specific alarms or failures occur, understanding their frequency and knowing how to prolong their life can significantly impact the BSC’s efficiency and cost-effectiveness.

Ultimately, a well-maintained BSC not only provides a safe working environment for microbiologists but also ensures the integrity of critical research and diagnostic work.

Leave a Reply

Want to join the discussion?Feel free to contribute!